One Platform. Many Applications.

Offshore and industrial operations take place in some of the most demanding environments in the world. Steel structures, vertical surfaces, confined spaces, strong currents, wave exposure, and hazardous zones are part of daily reality.

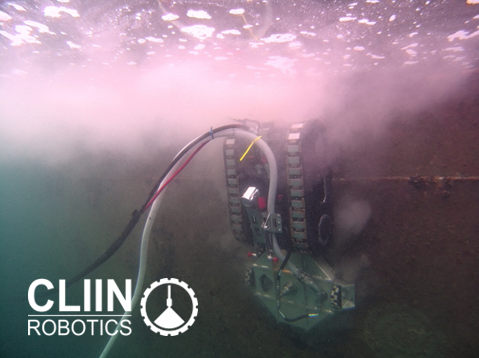

The CLIIN Magnetic Universal Crawler (MUC) is designed as a versatile robotic platform that operates in these environments and serves as a foundation for a wide range of applications.

Rather than being built for a single task, the crawler functions as a modular base where different tools can be mounted depending on the job. This enables one platform to support cleaning, inspection, measurement, and future offshore engineering tasks.

Learn more about the CLIIN Modular Robotic Crawler Platform on our Crawler page.

Core Capabilities of the Crawler Platform

The strength of the crawler lies in its physical capabilities.

- Operation on ferro-magnetic surfaces

- Strong magnetic adhesion

- Vertical and overhead movement

- Underwater operation down to 60 meters

- Operation in strong currents and wave-affected environments

- Suitable for ATEX Zone 2 environments

- Heavy-duty design

- Large payload capacity

- Cable-based control with simple and intuitive operation

These capabilities form the technological foundation that enables multiple applications.

A "Lego Block" Approach to Robotics

The crawler can be seen as a robotic "lego block".

The platform remains the same.

The tool changes.

Examples of tool types include:

- Cleaning tools

- Inspection cameras

- Measurement and sensing tools

- Surface preparation tools

- Custom third-party tools

This modularity allows customers and partners to configure the crawler for their specific needs without investing in entirely new robotic systems.

Proven Across Multiple Use Cases

The crawler platform has been deployed in a variety of real-world applications, including:

The crawler platform has been deployed in a variety of real-world applications, including:

- Tank cleaning

- Cargo hold cleaning

- Hull cleaning

- Confined space cleaning

- Underwater cleaning

- Steel structure cleaning

These use cases demonstrate that the platform is not theoretical. It is a real, operational product that has been used in demanding environments.

Built for Harsh Reality, Not Lab Conditions

Offshore and industrial environments leave little room for fragile equipment.

- The crawler is designed to withstand:

- Water and moisture

- Abrasive surfaces

- High-pressure water cleaning

- Temperature variations

- Mechanical impacts

This robustness reduces downtime and increases confidence in the technology.

Reducing the Barrier to Adoption

A common hesitation with robotics is whether the technology will work in real conditions.

By offering a platform that has already been used across multiple applications and environments, the crawler lowers this barrier.

Customers can recognise that:

- The platform is mature

- The technology is proven

- Value has already been delivered

This reduces the need for extensive demonstrations and long validation phases.

A Platform for Today and Tomorrow

A Platform for Today and Tomorrow

New tools can be added as needs evolve.

The crawler platform is designed to support future offshore engineering tasks beyond today's primary applications.

One platform.

Many possibilities.

Interested in discussing your specific application or challenge?

Submit an inquiry and our team will get back to you.

.png)